Top of Products > Solder-Aid > N2 System > N2 System Effect

| Examples of soldering defects | Effect of N2 System that prevents soldering defects | |

|---|---|---|

| A | ・Solder bridging ・Solder projection/Icicle ・Insufficient solder vertical fill of PTH ・Soldering defects caused by insufficient heat |

Antioxidant effect and preheating effect by N2 gas |

| B | Damaged components (capacitor, LED, etc.) by rapid heating | Preheating effect |

▼

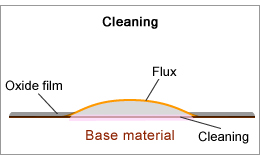

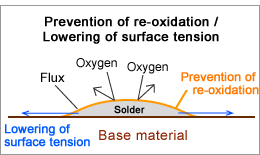

The use of nitrogen gas in soldering improves solderability because it prevents soldering joint from oxidation and gives preheating effect to workpiece.

View details Close

If solderability improves;

View details Close

Flux residue can cause corrosion on soldering points and it can cause product failure. Therefore it is important to clean flux residue. However, the use of some cleaning agent has been restricted due to the consideration of environmental issues (e.g. Fluorine regulation). Eventually the use of no clean flux has become more general.

ProblemSolderability with mildly activated flux is poor due to its low activity.

Acid rain melts lead (Pb) contained in soldering materials of waste electronic components and the melted lead (Pb) contaminates groundwater. To prevent this, the use of lead-free solder has been promoted.

ProblemWettability of lead free solder is poor, so that solderability of lead free soldering with the use of mildly activated flux becomes very poor.

▼

N2 System solves the problems of mildly activated flux by its antioxidant effect and preheating effect.

▼

Preheating effect helps lower set temperature without degradation of solderability and that results in reducing thermal load to heat-sensitive components.

View details Close

Preheating effect of N2 System helps lower set temperature without degradation of solderability and that results in reducing thermal load to heat-sensitive components.

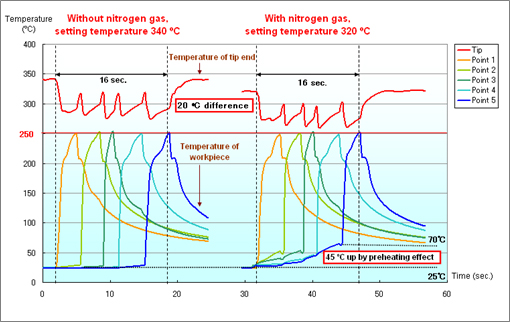

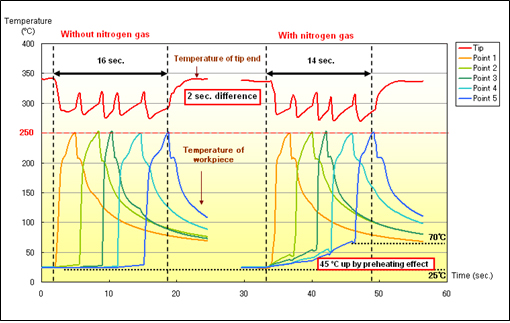

Look at the following graphs showing the difference of soldering time with / without nitrogen gas in case of HAKKO FX-951 and HAKKO FX-838.

Thermal recovery comparison graph of HAKKO FX-838 and HAKKO FX-951

| Test method: | Measure the time until the workpiece reached to 250℃ at 5 points; Setting temperature is 320℃ with nitrogen gas and 340℃ without nitrogen gas. |

|---|---|

| Board: | FR-1 (Paper phenol copper), single-sided |

| Component: | Connector |

| Tip shape: | T12-D24 without nitrogen gas T13-D24 with nitrogen gas |

| Setting temperature: | 340℃ without nitrogen gas 320℃ with nitrogen gas |

| Solder: | Lead-free solder (Sn-3Ag-0.5Cu) ø0.5 |

| Test method: | Measure the time until the workpiece reached to 250℃ at 5-points; Setting temperature is 320℃ with nitrogen gas and 340ºC without nitrogen gas. |

|---|---|

| Board: | FR-1 (Paper phenol copper), single-sided |

| Component: | Connector |

| Tip shape: | T20-D24 without nitrogen gas T20-D24 with nitrogen gas |

| Setting temperature: | 340℃ without nitrogen gas 320℃ with nitrogen gas |

| Solder: | Lead-free solder (Sn-3Ag-0.5Cu) ø0.5 |

Made a comparison of the work time to see how much N2 System can shorten the time by preheating effect.

Set the temperature at 340℃ for FX-951 and FX-838 without nitrogen gas. Set the temperature at 320℃ for FX-951 and FX-838 with nitrogen gas(20℃ lower).

Despite the 20℃ difference, there is no difference in the work time between the conditions with and without nitrogen gas.

This is the preheating effect (preheating by hot air) of N2 System. Preheating effect helps lower set temperature without degradation of solderability and that results in reducing thermal load to heat-sensitive components.

When having preheating effect…

View details Close

By preheating effect of N2, work time can be shortened.

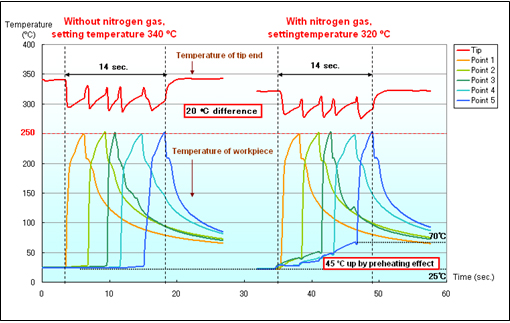

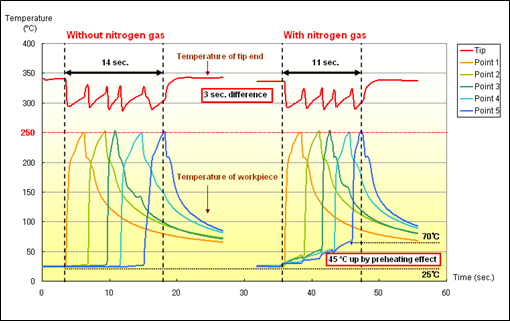

Work time comparison with or without N2 using Hakko FX-951 and HAKKO FX-838

Thermal recovery comparison graph of HAKKO FX-838 and HAKKO FX-951

| Test method: | Measure the time until the workpiece reached to 250℃ at 5-points. |

|---|---|

| Board: | Paper phenol copper board, single-sided |

| Component: | Connector |

| Tip shape: | T12-D24 without nitrogen gas T13-D24 with nitrogen gas |

| Setting temperature: | 340℃ |

| Solder: | Lead-free solder (Sn-3Ag-0.5Cu) ø0.5 |

| Test method: | Measure the time until the workpiece reached to 250℃ at 5-points. |

|---|---|

| Board: | Paper phenol copper board, single-sided |

| Component: | Connector |

| Tip shape: | T20-D24 without nitrogen gas T20-D24 with nitrogen gas |

| Setting temperature: | 340℃ |

| Solder: | Lead-free solder (Sn-3Ag-0.5Cu) ø0.5 |

Made a comparison of the work time to see how much N2 System can shorten the time by preheating effect.

Set the same temperature at 340℃ for FX-951 and FX-838 with nitrogen gas or without nitrogen gas.

Even if it is at the same set temperature, the work time can be shorten with nitrogen gas.

This is the preheating effect (preheating by hot air) of N2 System.

Preheating the workpiece enhances the solder flow so that the solderbility will improve.