Lineup

Desoldering / Rework/Desoldering Wire

Available in:

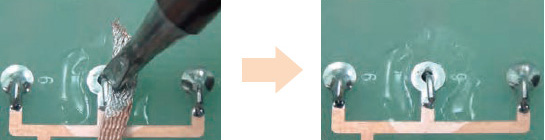

Desoldering a PTH component

Removal of solder bridge

Desoldering wire is used to remove solder from an elemental device or from patterns on a printed circuit board (PCB) from which surface-mounted devices such as BGA (ball grid array) have been removed.

Trick to remove solder well with the desoldering wire

Trick to remove solder well with the desoldering wireWrong use of the desoldering wire may tear patterns from a PCB or damage discrete components. In order to prevent these problems, make sure to take the preventive measure below:

Apply a bit of solder to the tip of soldering iron.

Apply a bit of solder to the tip of the desoldering wire. Cut the soldered tip of the wire at an angle of 45 degrees. Solder should remain attached.

Preliminary soldering improves heat conductance. Click here for details.

Desoldering completed!