A sealer that's portable but can even seal the thicker bags used for tea, coffee beans, and health foods!

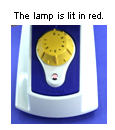

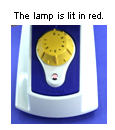

Lamp colors indicate progress of work procedure.

- Easily provides anyone with a skillful finish.

- Press the handle.

- During heating, lamp is lit in red.

- During cooling, lamp is lit in green.

- When sealing is completed, the lamp turns off.

Sealable bags: Max. seal width: 5mm; Max. seal length: 200mm; Max. bag thickness: 0.4mm (aluminum-evaporation bag, gazette bag, etc.).

FV-801

Max. seal width: 5mm; Max. seal length: 350mm; Max. bag thickness: 0.4mm

FV-802

Max. seal width: 1.6mm; Max. seal length: 200mm; Max. bag thickness: 0.2mm

Easy to use for packaging presents and wrapping small items

- Packaging can be performed in homes, stores, etc.

- Can also be used with roll films.

Sealing-only type

Compact size does not require a lot of space.

- 100 (W) x 250 (H) x 400 (L) mm

- Routing direction of power cord can be selected.

Options

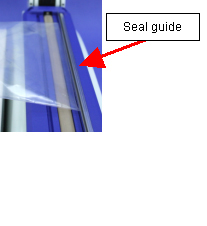

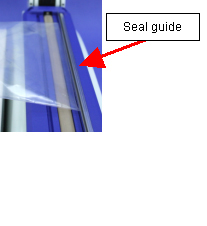

- Seal guide···Enables a seal margin to be kept at a constant 8mm.

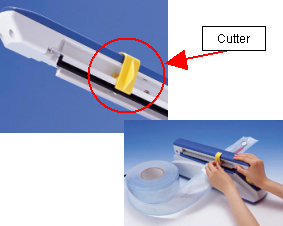

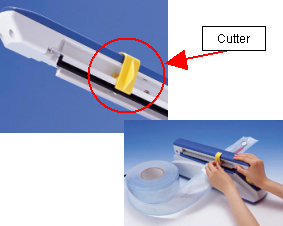

- Cutter assembly···Can cut roll films.

Options

Usage/Applications

Operating procedure

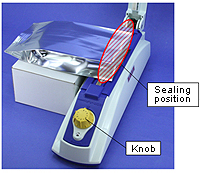

1. Setting before sealing

Set the heating time adjusting knob according to the material and thickness of the package film, and adjust the sealing position.

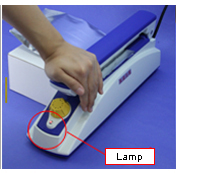

2. Heating (Lamp is lit in red.)

When the handle is pressed down, the lamp is lit in red.

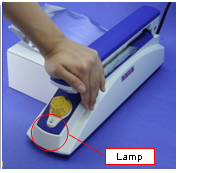

3. Cooling (Lamp is lit in green.)

Check that the lamp has turned green while continuing to press down the handle. The lamp is lit green.

4. When the lamp goes out, it means that sealing has been completed.

Raise the handle to check finished conditions.

Options: How to use?

- Seal guide・・・Enables the seal margin to be kept at a constant 8mm.

- Cutter assembly・・・Can cut roll film.

Caution: Be careful not to cut your finger, etc. when using the cutter.

Heat adjustment table for sealing

- The thickness values shown are the total of 2 layers or more.

- The values in the above table are reference values. The actual value will vary according to the material and voltage. Adjust the setting to the optimum value.