Lineup

Soldering Iron/Station Type

Available in:

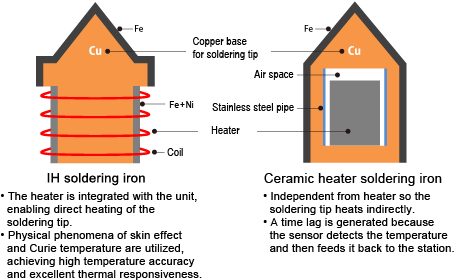

HAKKO's IH soldering station achieves excellent thermal performance in soldering with the principle of IH (High-Frequency Induction Heating) that heats a soldering tip directly. The thermal power that does not decline even with a smaller tip is very effective in micro soldering.

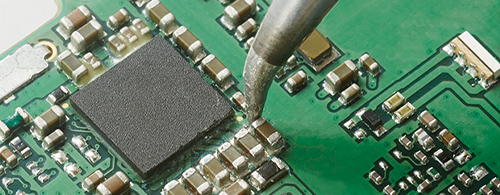

Unlike resistance-based heating systems that control temperature by turning heater power on and off via a sensor, with an induction heating system the soldering tip itself produces heat and maintains a constant temperature, enabling a small soldering tip to handle high thermal capacity, high-density substrates.

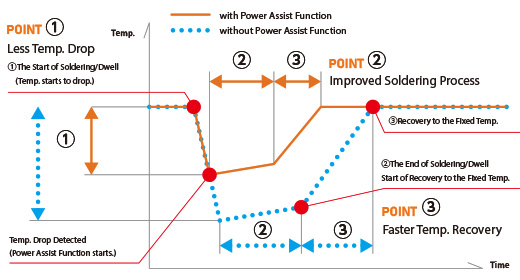

By monitoring RF output, the station detects tip temperature drop during the soldering process and then increases the output. This function minimizes tip temperature drop and helps the temperature recover quickly. As a result, it can improve soldering efficiency and quality.

The mode is to boost tip temperature slightly. It can fill out the slight temperature gap among tips and minimize the individual differences in tip temperature. Also it is useful when some extra power is needed.

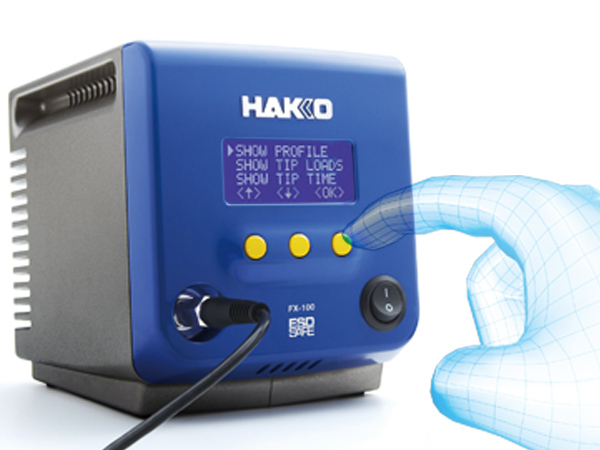

FX-100 makes the operation of the station stress-free by showing various information and operation menus on its display.

It also shows the output power graph in real-time of the soldering process.

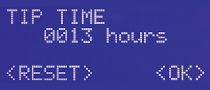

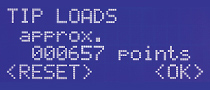

FX-100 can record information such as "TIP TIME" and "TIP LOADS". Such information can be the reference for the timing of tip replacement.

The compact body design make the station handy.

”TIP TIME” is the cumulative running time on the tip. Alert can be set for the specified tip usage time for scheduled tip replacement.

"TIP LOADS" is the number of estimated soldering points.

It can be an indication of the tip condition.

The power of IH makes difference in the soldering on high-density or multi-layered P.W.B.

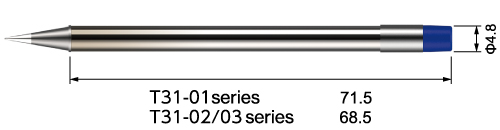

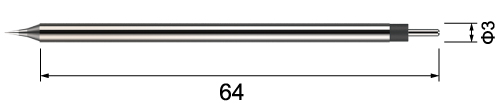

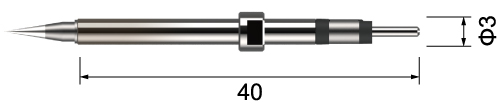

The wide lineup of T31 series soldering tips supports a variety of works.

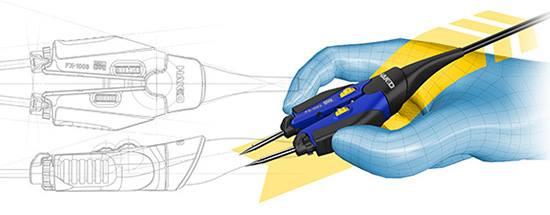

The iron is built with the user-friendly grip and cord for better operability.

3 different colors of the sleeve can be used depending on tip shapes, solder alloys, works, and other conditions.

It is suitable for the soldering for fine works such as 0402 components under a microscope.

The power that does not decline even with very fine and small tips is ideal for soldering on micro components.

The slim and light grip design for excellent operability helps precise and micro works.

2 different colors of the sleeve can be used depending on tip shapes, solder alloys, works, and other conditions.

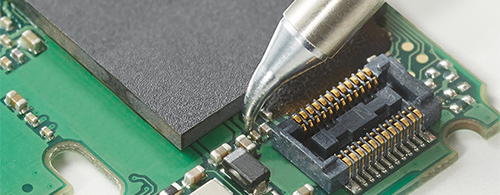

Micro and precise tip lineup for a variety of rework.

FX-1003 has tips to rework on 0402 components.

The handpiece with the compact and asymmetric design with heat-resistant covers fits the hand, gives better stability, helps reduce the burden of operation, and supports precise and accurate works.

Tip temperature is fixed by tip series. No setting temperature is required before use.

| Temp. | FX-1001 (Standard) | FX-1002 (Option) | FX-1003 (Option) |

|---|---|---|---|

| 450°C | T31-01 series | — | — |

| 400°C | T31-02 series | T35-02 series | T38-02 series |

| 350°C | T31-03 series | T35-03 series | T38-03 series |

Because there is no heating element, there is no chance of degradation of a heating element, and no calibration is required.

Because tip temperature is fixed by a physical phenomenon, there is no chance of overshoot.