Lineup

Soldering Iron/Solder Feed System

Available in:

Amount of solder feed can be controlled by the combination of feed "time" and feed "speed". (Only in AUTO mode)

| AUTO mode | To feed solder in the specified time and at the specified speed once the switch is pressed. (Only in AUTO mode) |

|---|---|

| MANUAL mode | To keep feeding solder at the specified speed while the switch is pressed and held. |

The function to draw back solder by the specified length after feeding is equipped.

It reduces the thermal impact of the high-temperature tip on solder and flux.

Set the appropriate conditions when using the product with an automatic machine.

How to use the solder return mechanism

As shown below, when solder is cut with a V-groove it enables the release of gas pressure generated by the flux, thereby suppressing splash. However, because the V-groove exposes the flux to outside air the solder cannot be stored for a long period of time.

When using solder with the HAKKO 374, you can groove the solder that you require.

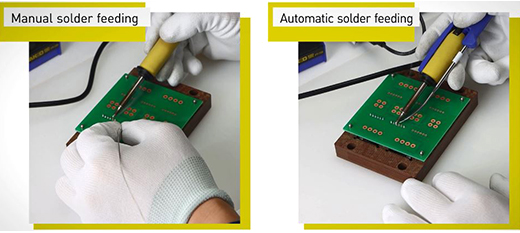

The combination of the new tube unit and guide pipe assembly (options) achieves the one-handed soldering just like manual soldering, one hand for holding a soldering iron and the other hand for feeding solder wire.

The new tube unit that feeds solder from the underside of the tip is now in the lineup.

Because the new guide pipe assembly is designed to be set at closer to the tip, the size of the iron with it is smaller than the iron with the conventional guide pipe assembly, and it improves the handling of the iron. The one-handed soldering just like manual soldering can be achieved.

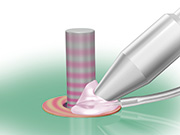

The combination of the new tube unit and guide pipe assembly feeds solder from the underside of the tip and makes it possible to obtain "heat-bridge effect" in which molten solder helps heat transfer to enable ideal soldering.

It is the phenomenon that the heat from the tip being transferred quickly to soldering joint area via molten solder.

It is one of the important elements to achieve good soldering.

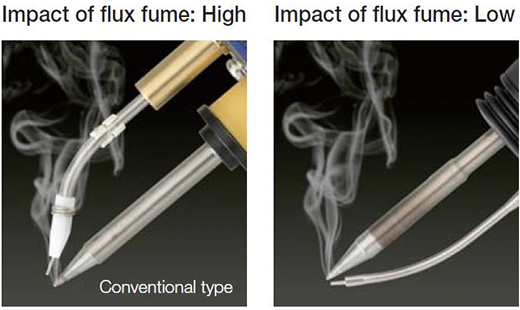

The maintenance of the new guide pipe assembly is easy because it will have less residue of flux fume and clogging with the residue while feeding solder from the underside of the tip.

The position of solder feeding is critical to soldering quality. The new tube unit makes it easy to adjust the solder feeding position by holding the guide pipe assembly tightly with the two parts.

The installation on a soldering iron is simple and easy.

Tip can be replaced without removing the tube unit and the adjusted guide pipe assembly.

It saves the trouble of adjusting the position of solder feeding.

The tip cleaner FT-720 cleans a tip quickly and surely even having the guide pipe assembly on a handpiece.

The dedicated receptacle makes the conventional iron holder accept the iron with the new guide pipe assembly.

The new type, feeding solder from the underside of the tip, is recommended for improving work efficiency.

For the applicable soldering irons, please refer to the optional parts combination table.

HAKKO 373・374 Optional Parts Combination Table

The auto-solder feed system with the feeder pen enables the control of amount of solder to feed.

It is useful for any type of soldering iron.

| Usable Solder Dia | 0.6/0.65mm | 0.8mm | 1.0mm | 1.2mm | 1.6mm | |

|---|---|---|---|---|---|---|

| Feeder Pen | C1234 | C1235 | ||||

| Switch | Foot Switch | B1649 | ||||

| Feeder Switch | B2124 | |||||