Lineup

Top of Products > Auto-Soldering System Auto-Soldering System Soldering Iron Desoldering / Rework Preheater Soldering Pot Thermometer / Soldering Tester Fume Extractor Solder / Flux Static Control Tool for Lead and Wire Shrink Packaging / Heating Gun Glue Gun / Sealer Hobby > Auto-Soldering Robot System > HU-200

Auto-Soldering System/Auto-Soldering Robot System

Available in:

All-in-one soldering robot system into which the solder feed controller and the programming software are incorporated. All operations, such as soldering conditions, including solder feed amount and heating time, can be controlled collectively by the tablet PC provided as standard equipment.

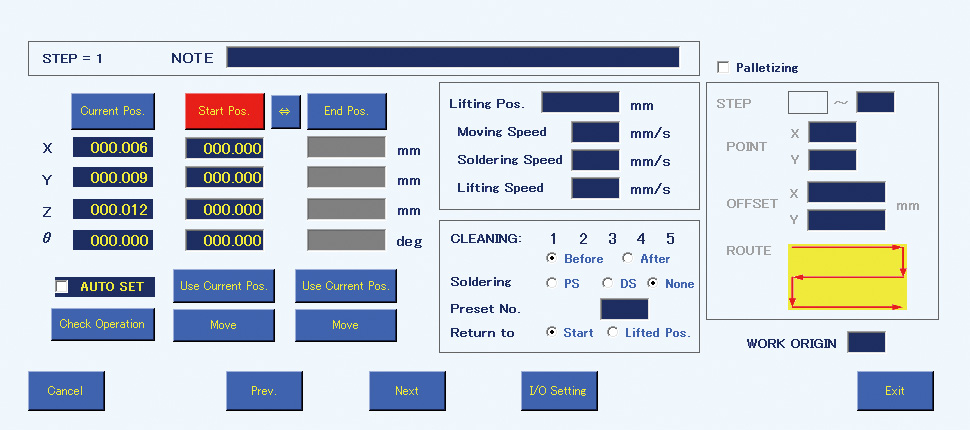

Without a teaching pendant or connecting to a PC, you can set everything for programming or soldering conditions on the same screen by operating the touch panel on the tablet supplied as one of the standard accessories.

The easy programming software (Easy Programming Software II) is pre-installed, allowing you to create soldering programs easily without expert knowledge about robots.

This software also allows you to control the number of accumulated soldering points and work time. Thus, only setting the tip replacement timing enables the robot to undergo an automatic stop.

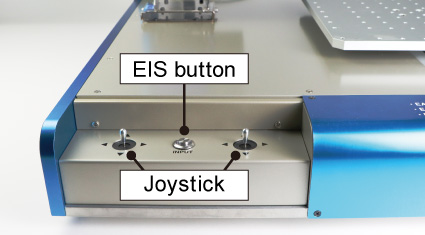

Teaching can be intuitively made using the joystick. The joystick use feeling such as speed and inching pitch can be easily changed. When performing delicate position adjustment, setting the mode to inching pitch allows you to operate the robot as finely as 0.01 mm unit at minimum. Using the EIS (Easy Input Switch) allows you to input the coordinate of robot and feed steps automatically, which can reduce the teaching time.

When arranging multiple identical PWBs for teaching, the function allows programming simply by inputting the offset values from the original position.

If the soldering points are arranged at regular intervals, like connectors, you only need to position one point. And then, the soldering of the rest is ready for finish by inputting the travel distance and the number of repetitions once.

A bar code reader allows one to select a program automatically from the bar code or QR code pasted on the P.W.B. This prevents malfunction by human error.

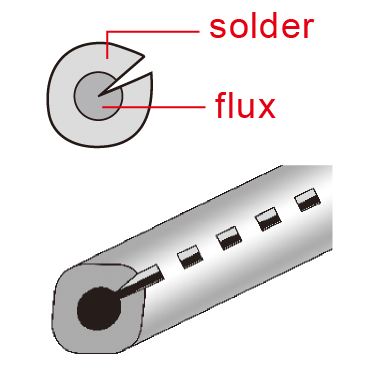

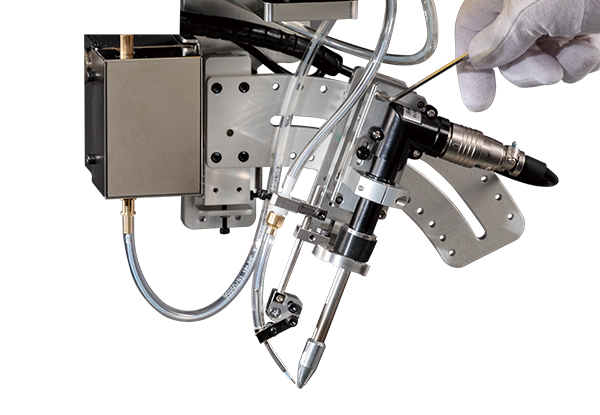

Making a V-groove on the solder wire reduces flux and solder ball scattering.

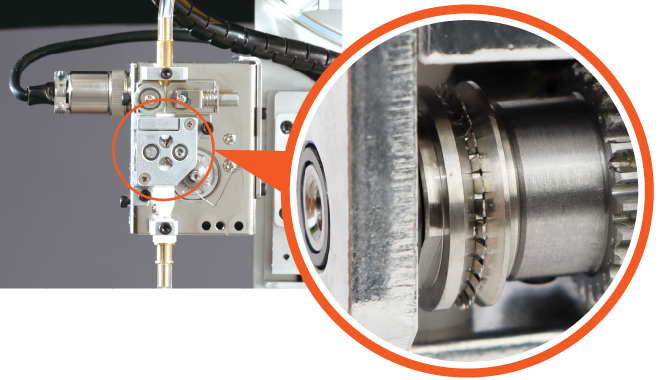

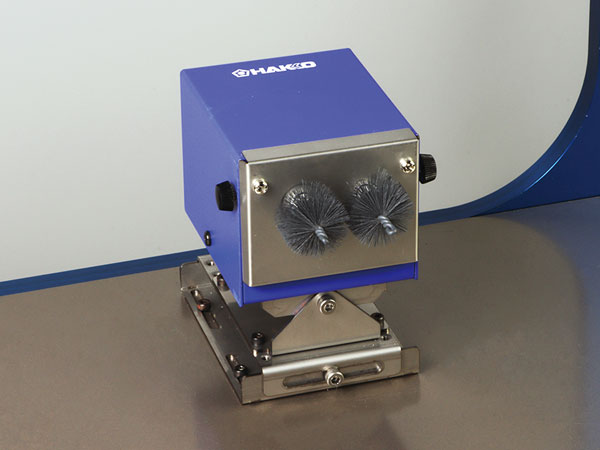

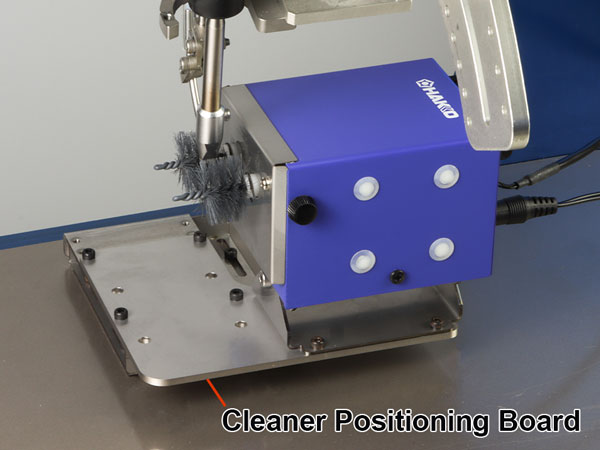

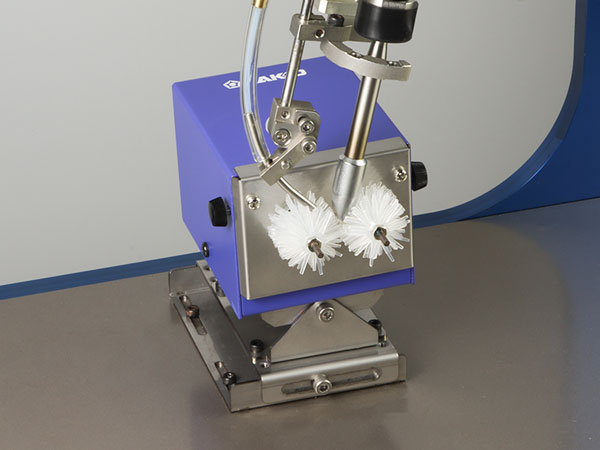

A brush-type tip cleaner is employed.

This brush-type tip cleaner can remove excess solder and carbide of flux from a tip.

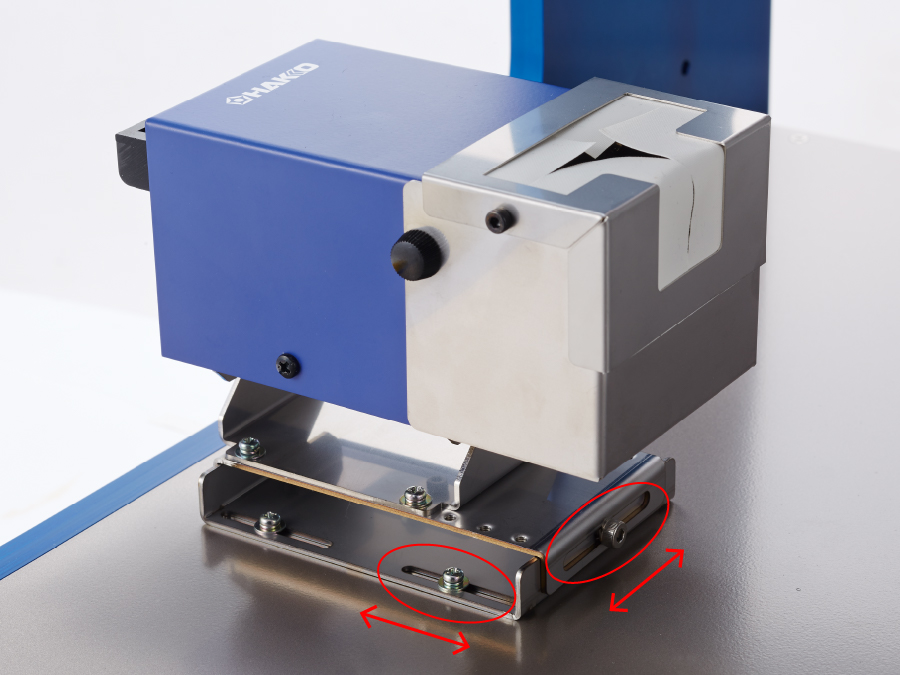

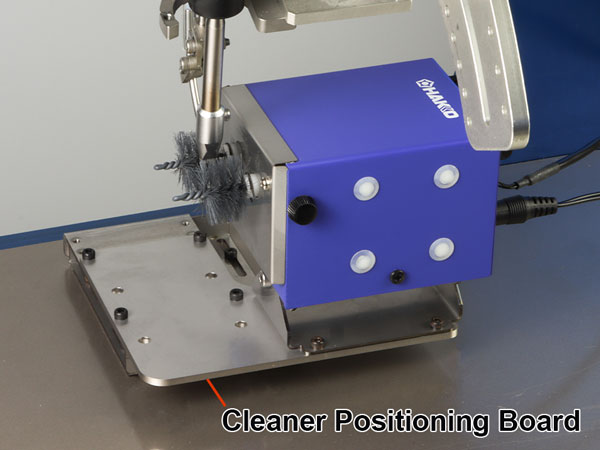

With the cleaner positioning board, the tip cleaner can rotate 90 degrees.

Silicone brush has a lifetime of 21 times longer than the standard one (Part No.A1567) made of steel*. * Based on our in-house test

Details from here News

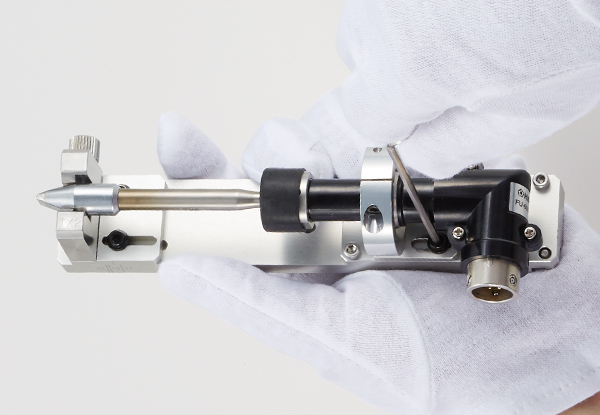

Adjustment work after tip replacement can be done quickly and easily with the jig for tip positioning.

It improves the existing issues such as "non-wetting of solder due to poor heating" and "insufficient through-hole-fill" with 300 W high power.

There is a possibility that you can reduce the working hours if it is heat-consuming work.

It works as a 140 W soldering iron for fine works.

Forty types of TX2 series soldering tips are lined up for a wide range of soldering conditions.

Appropriate tip selection from various shapes can improve the quality and efficiency of soldering and reduce running costs.