Lineup

Thermometer / Soldering Tester/

DISCONTINUED

Your searching product was discontinued to be replaced by upgraded model as shown below.

Service parts are no longer available, but consumable parts are still available.

| Discontinued Model | Succeeding Model |

|---|---|

| FG-101 Discontinued (YYYY/MM): 2019/11 |

|

191-212 and 191-212C has been discontinued.

And, the succeeding model of 191-212 and 191-212C is AS5000.

Click here for more information about Sensor AS5000.

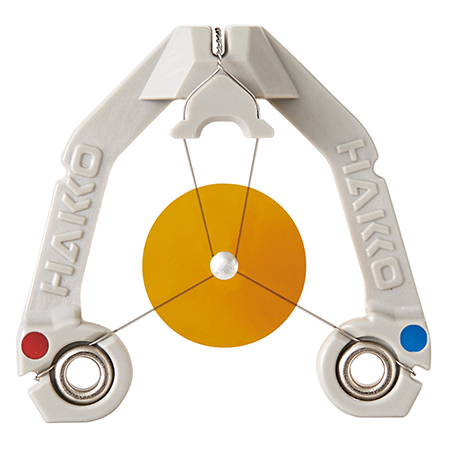

Long-life sensor AS5000