MAINTENANCE/TROUBLESHOOTING/APPLICATION EXAMPLES

Top of Support & Service > MAINTENANCE/TROUBLESHOOTING/APPLICATION EXAMPLES > FT-710: Suddenly, the solder cannot be removed when tip cleaning. Why?

The possible causes are assumed as below. Please check.

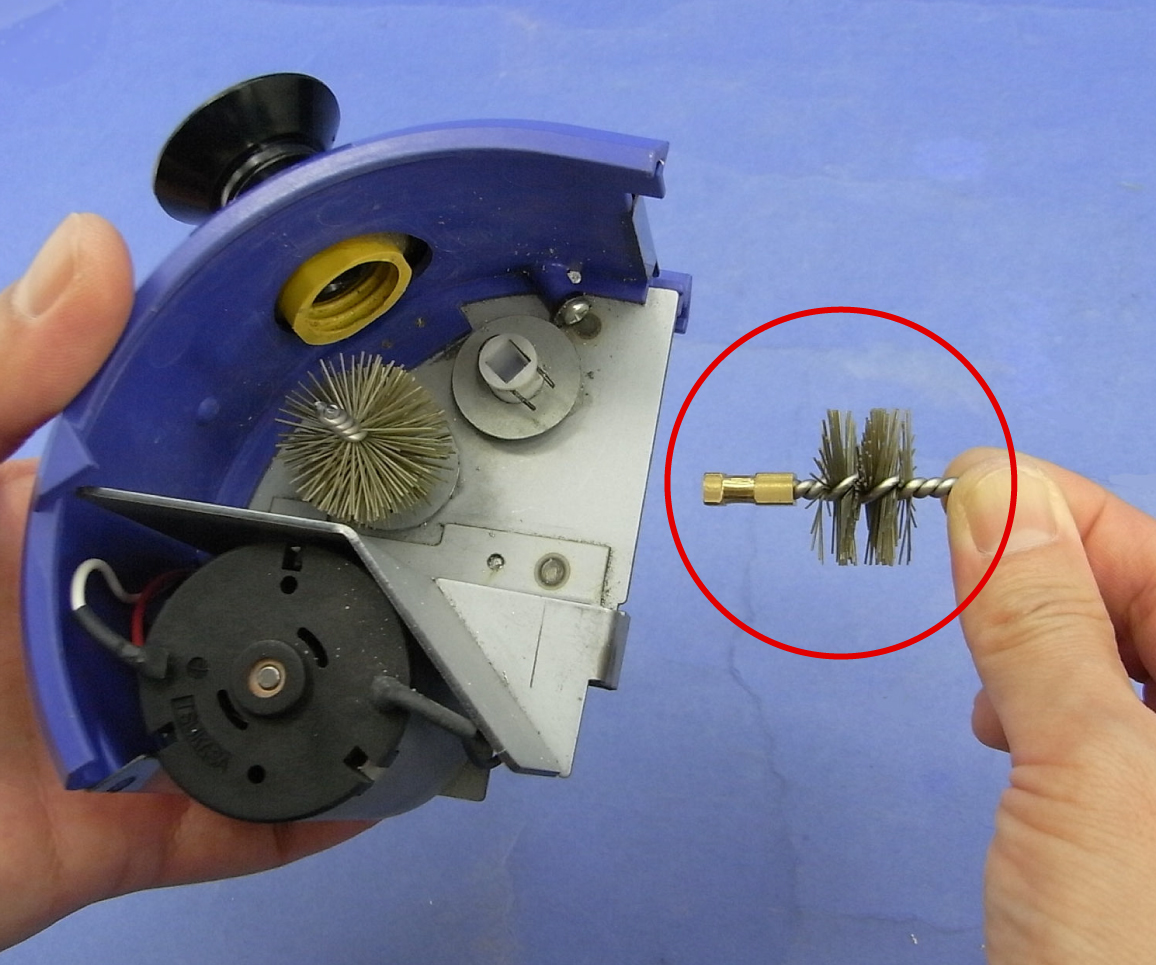

While using, solder wastes get accmulated in the brush little by little. Then, eventually it prevents solder from being removed.

Replace the brushes with the new ones.

For more details, refer to Maintenance and replacement frequency of the cleaning brush.

Usually, the soldering tip position to the brush is aligned after the soldering iron is turned off in cooling down enough.

However, the resin brushes can be melted if aligning the soldering tip while it is still hot.

Check the condition of the brushes and replace them with new ones if brush tips have been melted.

For more details, refer to The procedure of aligning the soldering tip.