MAINTENANCE/TROUBLESHOOTING/APPLICATION EXAMPLES

Top of Support & Service > MAINTENANCE/TROUBLESHOOTING/APPLICATION EXAMPLES > Solder does not wet on the surface of the new tip

Even a new tip will oxidize if leaving the iron powered on for over 30 minutes. Because of the oxidation, solder does not wet on the tip.

Leaving the tip at the temperature of 470 ℃ for over 30 minutes・・・

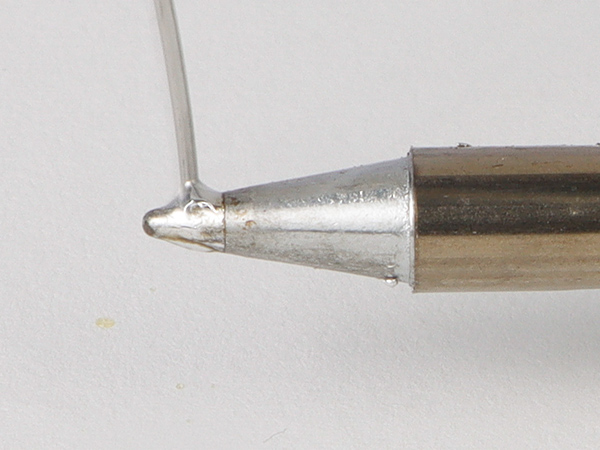

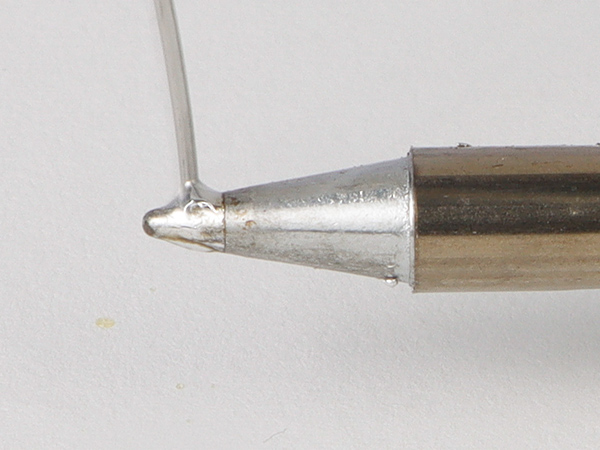

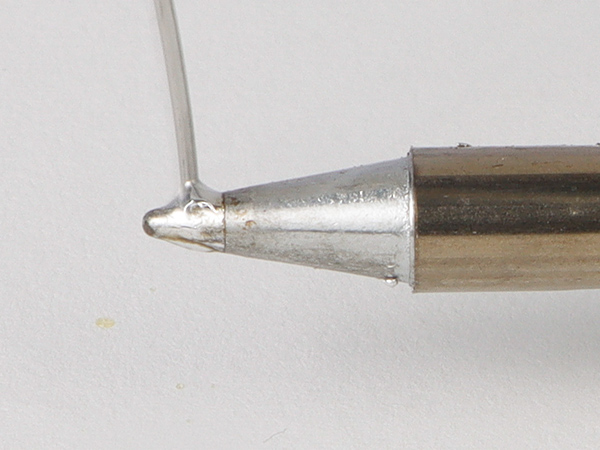

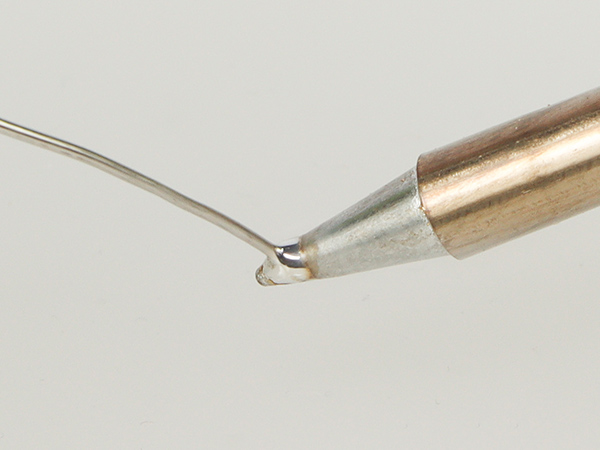

Before turning off the power of the iron or leaving it powered on temporarily, feed the solder to the tip end. Once the molten solder covers the tip surface, the solder prevents the tip from oxidation by blocking the air, even leaving the iron powered on for a while.

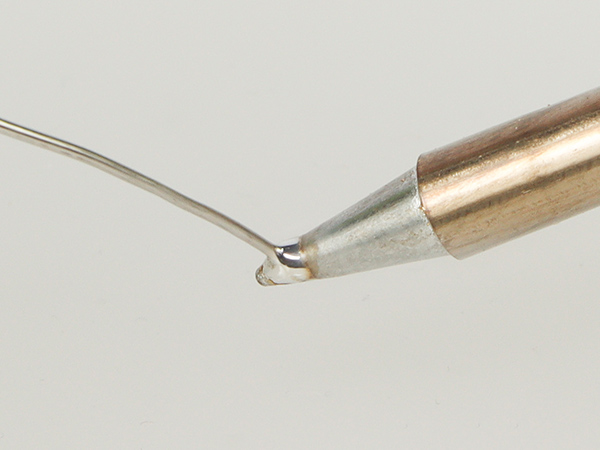

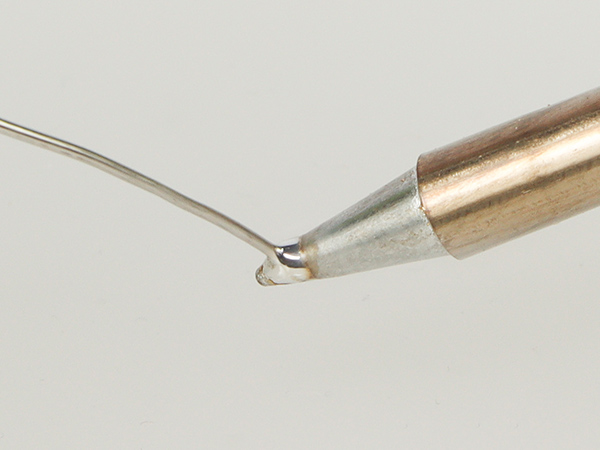

Set the tip temperature at around 350℃.

Set the tip temperature at around 350℃.

If solder does not wet on the tip surface again even after the cleaning methods above, replace the tip with the new one.