Lineup

Top of Products > Auto-Soldering System Auto-Soldering System Soldering Iron Desoldering / Rework Preheater Soldering Pot Thermometer / Soldering Tester Fume Extractor Solder / Flux Static Control Tool for Lead and Wire Shrink Packaging / Heating Gun Glue Gun / Sealer Hobby > Auto-Soldering Unit > FU-500/FU-601

Auto-Soldering System/Auto-Soldering Unit

Available in:

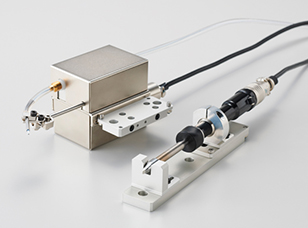

FU-500 / FU-601 can be combined with various robots and other actuators to build an automatic soldering process at low cost.

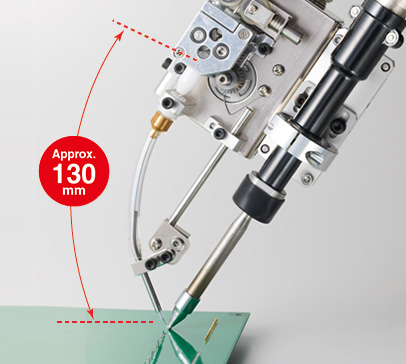

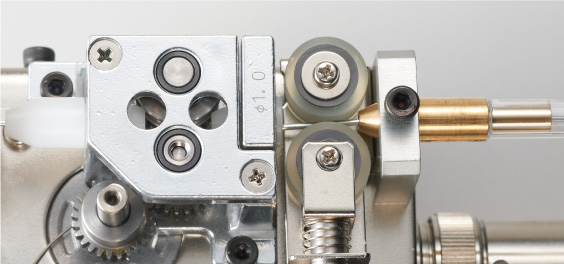

FU-500 features a compact drive unit that allows the solder feed unit to be brought closer to the iron. This adaptation makes it possible to increase the repeat accuracy of amount of solder feeding.

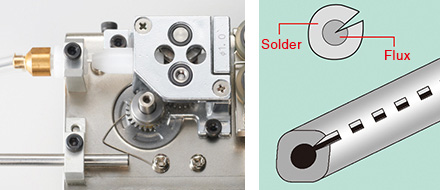

As countermeasure against scatter of flux and solder balls, the unit is equipped with a mechanism that perforates into the solder wire as standard. It is also possible to change acceptable solder wire diameter by simply replacing the pulley unit.

As the unit is capable of handling extremely small solder diameter of 0.3 mm, it can be used for delicate soldering jobs.

Supported solder diameter 0.3 mm to 1.6 mm.

100 programs each configurable for "Point soldering" and "Drag soldering" at low price.

Programs can be edited by PC via a USB connection.

Adjustment of the position of solder feeding to the tip is critical for auto-soldering systems. FU-500 lets you adjust the solder feeding position just by turning an adjustment screw with a wrench.

With an optical sensor for solder movement, FU-500 can detect solder clogging, slipping and the end of the roll.

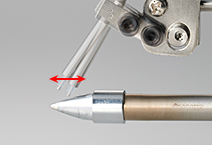

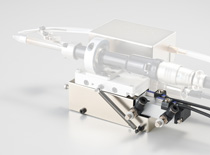

The position of the tip end can be easily adjusted using the tip adjustment jig unit included with FU-601. Work can be started just by removing the iron from the main unit by removing two screws, positioning the tip using the tip adjustment jig unit, and returning the iron to the main unit.

Using another iron (FU-6001 or FU-6002) makes it possible to install a new tip in advance, minimizing equipment downtime.

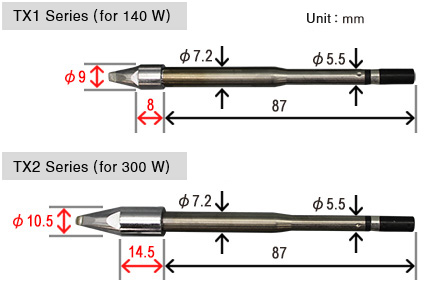

* Two types of tip adjustment jig units are available: one for TX1 series and another for TX2 series.

FU-601 can provide excellent thermal recovery characteristic with a high performance composite tip, a tip integrated with a heating element and sensor.

40 types of TX2 series soldering tip are lined up for a wide range of soldering conditions.

The use of appropriate tip can not only improve quality and efficiency of soldering but also reduce running costs.

Click here for more information about TX2 series soldering tips.

Tip temperature can be preset in six settings. Preset temperatures can be called from soldering conditions in the solder feed unit.

Select the one to meet your requirement.

FU-6001 is straight, and FU-6002 is L-Shaped Iron.

FU-6001

FU-6002

Simply attach the optional N2 adapter to the iron and install a nozzle assembly that matches the tip to perform N2 soldering.

The slide unit allows the soldering unit vertical movement.

As the solenoid valve comes pre-wired, the unit can be used by simply connecting to FU-500 via special connector and supplying compressed air externally.

If height varies during drag soldering due to the angle or other conditions of the sample, height variations can be absorbed by attaching this slide unit to the soldering unit.

The tip cleaner's rotating brush can remove not only excess solder but also flux carbides, which are difficult to remove from tips by compressed air.

It is possible to turn the brush on and off via an external signal.

The tip thermometer unit can be placed under the tip to measure the tip temperature of an auto-soldering unit.