Lineup

Desoldering / Rework/Rework staion

Available in:

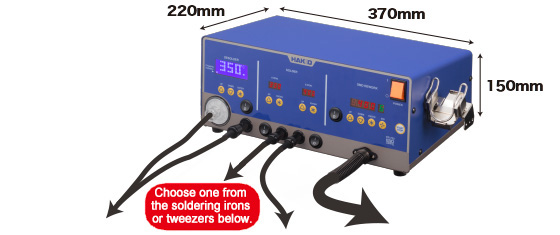

Other than the standard handpieces of 140 W desoldering gun, M-type soldering iron and high power & large volume hot air, there are 4 more applications. Consumed tip nozzle and heating element can be replaced individually, and running cost is much lower than the composite type.

| S t a n d a r d |

Desoldering gun FR-4103

- 140 W high powers enable perfect desoldering for the components on multi-layer PWB.

- A wide selection of nozzle, with the addition of new types, is available for a variety of desoldering works.

|

Soldering iron M type FX-8801

- Takes T18 tip series with improved thermal conductivity

|

Hot air handpiece

- It enables quick removal of components with high power and large volume hot air for a various kinds of rework.

- Vacuum function with indicator makes it possible to remove components easily and safely.

|

|---|---|---|---|

| N61 series nozzles | T18 series tips | N51 series nozzles |

| O p t i o n |

Soldering iron L type FX-8805 |

N2 Soldering iron FX-8802 |

One-hand Manual-solder-feed iron FX-8803 |

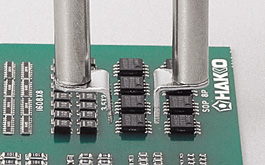

SMD hot tweezer FX-8804 |

|---|---|---|---|---|

|

|

|

|

|

| View the details | View the details | View the details | View the details | |

| T19 series tips | T18 series tips | 950/FX-8804 series tips | ||

Increasing the power to 140 W from 50 W of our previous models (HAKKO 474・475), it can make it easy to desolder on multi-layer PWB which was never an easy job, and it can also shorten the process time.

A wide selection of nozzle, with the addition of new types, is available for a variety of desoldering works.

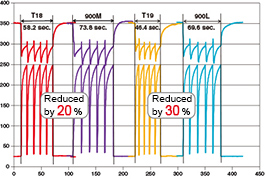

Thermal conductivity has been increased by reviewing external configuration and internal structure of 900 tip series.

Now T18 and T19 tip series are selectable depend on work environment.

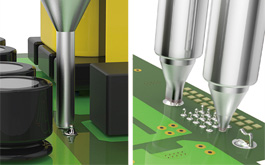

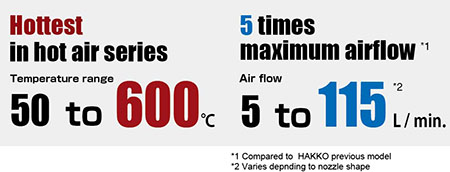

670 W high power and large volume hot air improves work efficiency.

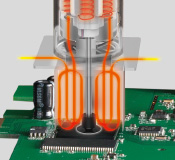

The new nozzle improves work efficiency with uniform heating by hot air convection inside the nozzle which is created due to vents on the nozzle top. (only with BGA nozzles)

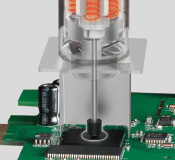

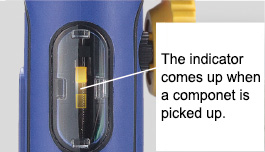

The vacuum pick up function is to pick up a component with a suction pad and vacuum. It will pick a component only after the hot air melts solder joints. This can avoid an error to peel off the land by removing a component with excessive force.

By pre-setting pickup function, a component can be picked up automatically when solder is melted. Then, the indication comes up and the moment of picking up will be visible.

Even a component and solder joints cannot be seen as covered by a nozzle, easy and safe picking up is possible.

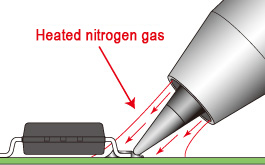

The N2 gas runs into the nozzle assembly and covers over the soldering tip. It prevents the soldering tip and the heater from being readily oxidized and performs great role as a preheating.

Two effects of N2 system, preventing oxidation or preheating effect, can improve soldering defects such as bridging, protrusion icicle, insufficient solder filling in PTH, etc.

T18 tips series are compatible with this application.