Lineup

Soldering Iron/IoT Capable Type

Available in:

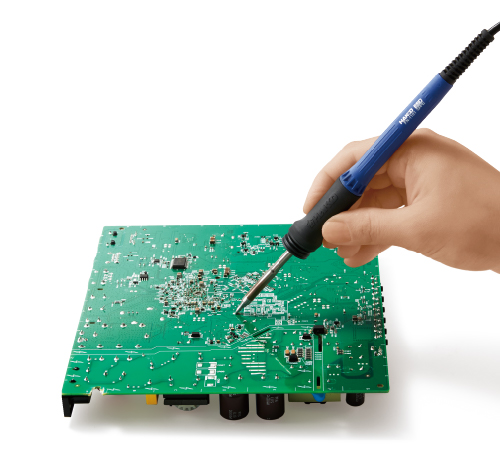

The combination of a soldering iron FN-1010 and a thermometer FG-100B optimizes manual soldering by improving traceability and minimizing human error with the use of IoT technology.

A memory chip in the T36 series tip collects the information described below.

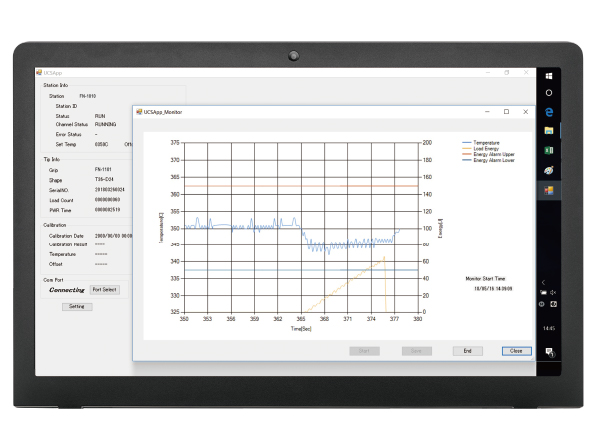

Soldering information is collected and saved in real time.

You can observe the ongoing operation on the LCD.

It is also possible to save on a PC to observe.

The dedicated software is available for download on our website.

Click here to download the FN-1010 software.

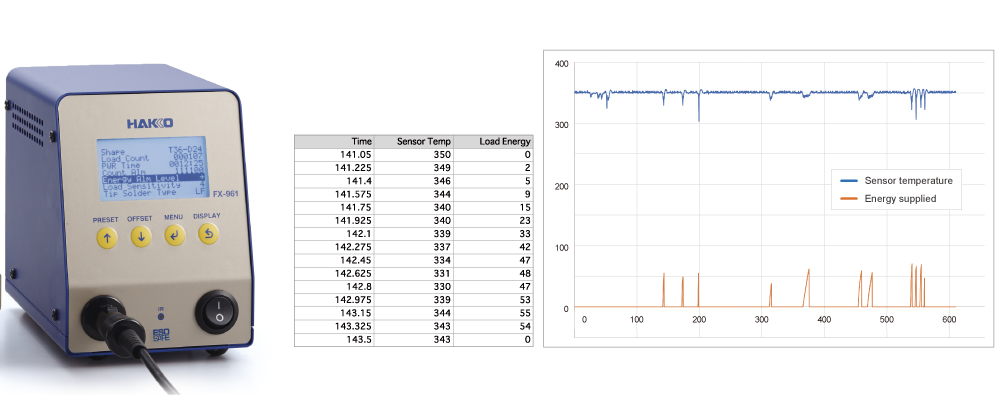

By visualizing the energy supplied by the soldering iron tip during soldering, it is now possible to manage the factors of soldering work that were not possible before.

Optimizing the soldering conditions with the collected data is also possible.

Automatic calibration and correction can be completed by sending the measured temperature value of the thermometer (FG-100B/FG-101B), via infrared.

Since the results of temperature measurement, calibration, or offset can be saved automatically, temperature management with human error-free is possible.

The built-in sensor of the tip inside makes it possible to use auto-sleep and auto-shutoff functions without connecting the station and the iron holder, and it helps to lay out the station and iron holder freely in the working space.

A motion sensor detects free fall and cuts the power automatically.

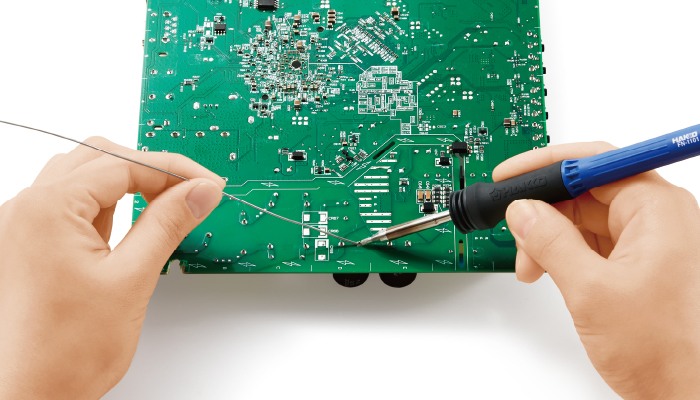

Solder balls during tip cleaning can be reduced by 99% with devised cleaner designs such as a smaller aperture, set angle, and position of the cleaning wire.* In-house comparison

The newly designed iron holder allows easy and safe tip replacement with a tip removing attachment and tip insertion holder.