MAINTENANCE/TROUBLESHOOTING/APPLICATION EXAMPLES

Top of Support & Service > MAINTENANCE/TROUBLESHOOTING/APPLICATION EXAMPLES > Periodic inspection for desoldering tool

For using a desoldering tool in good condition, it is recommended to conduct adaily check after every useand a periodic inspection depending on the frequency of use in a correct way.

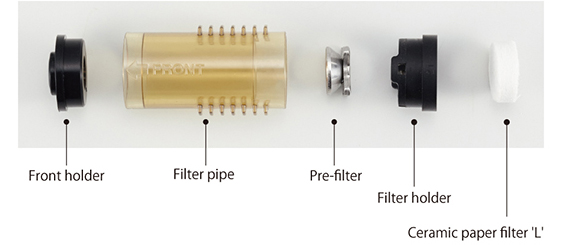

Filters prevent flux from invading the station.

Always install filters when using a desoldering tool and inspect them periodically to ensure that they are not contaminated with flux or solder.

Early replacement can prevent solder suction performance and pump failure.

Check the condition and replace deteriorated parts.

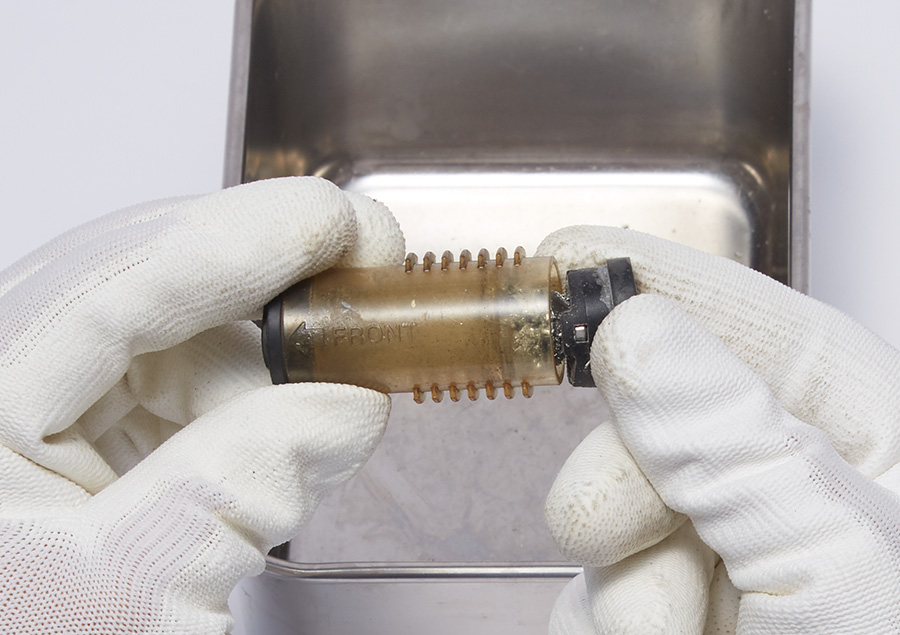

The filter pipe assembly, surrounding area, and solder remaining inside are extremely heated.

Ensure the unit is powered off and that it has cooled down enough before replacement work.

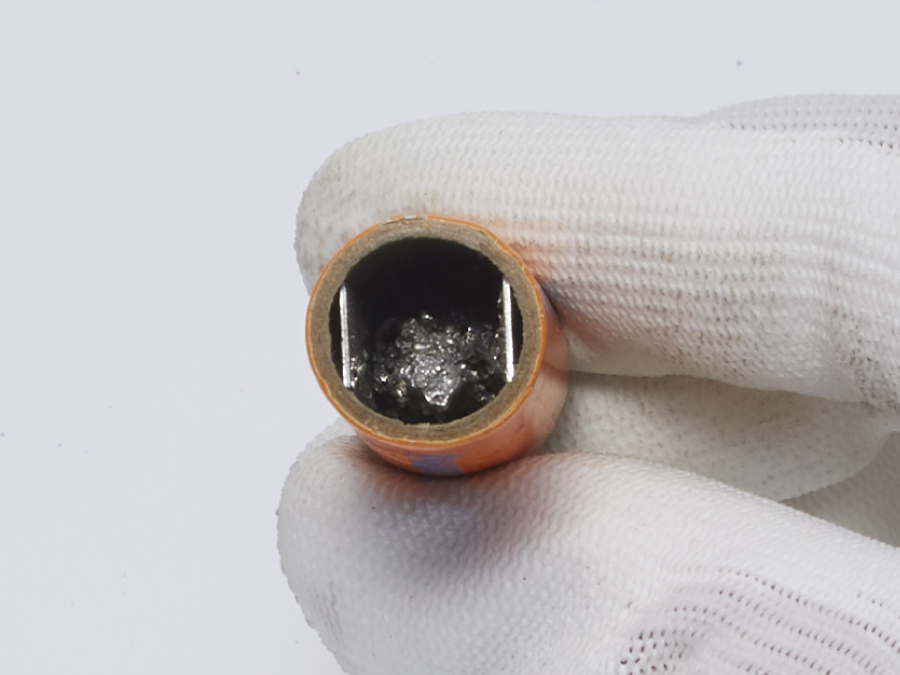

Remove the filter pipe assembly with a slight pull.

Replace if damaged or cracked, as this can cause a reduction in suction pressure.

Front holder (Part No. A5017)

Front holder (Part No. A5030)

Replace if damaged or cracked, as this can cause a reduction in suction pressure.

Filter holder (Part No. A5018)

Filter holder (Part No. A5031)

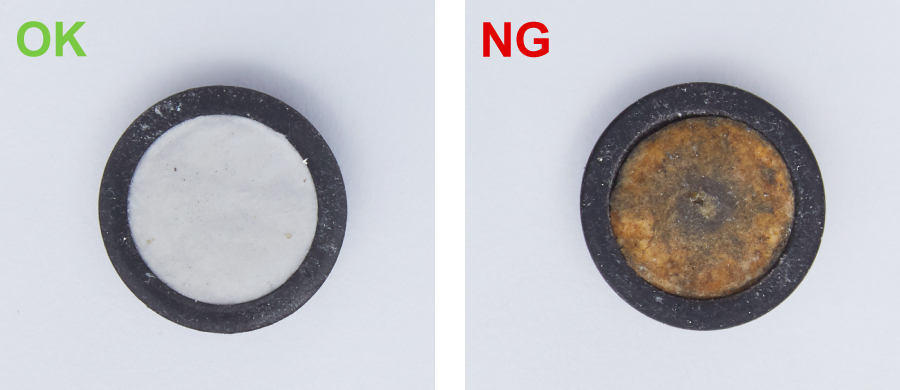

Remove the solder after removing the pre-filter from the filter holder not to cause damage to the filter holder.

If the filter pipe is dirty, clean it with waste cloth moistened with alcohol to check whether any solder is stuck inside or not.

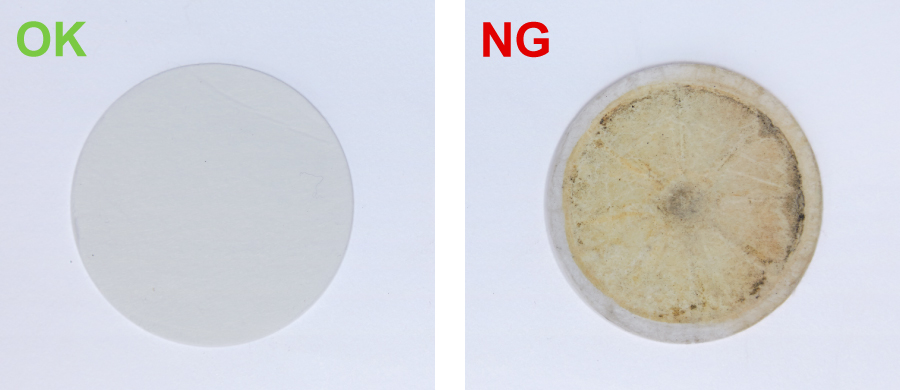

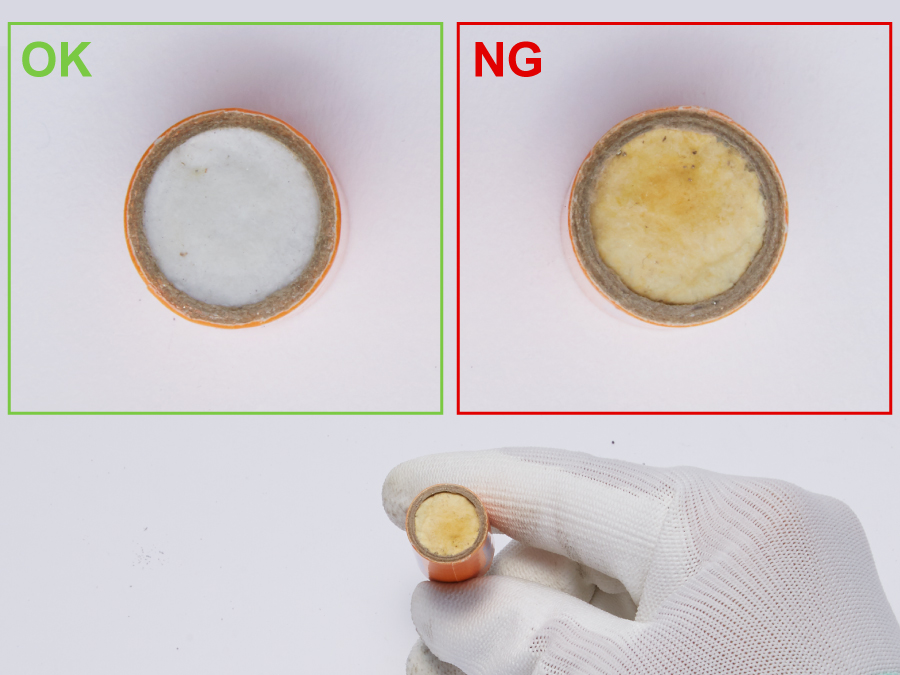

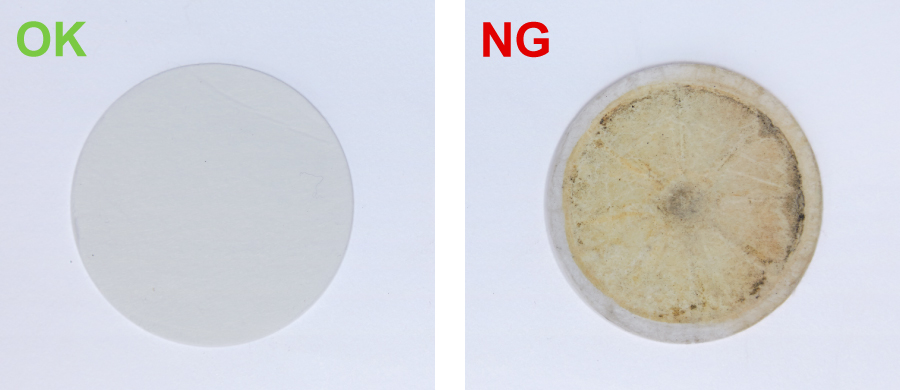

When the filter is soaked with flux, it becomes discolored and hard.

Ceramic paper filter (Part No. A5045)

Ceramic paper filter L (Part No. A5044)

Check the condition and replace any parts that have deteriorated.

When the filter is soaked with flux, it becomes discolored and hard.

Check the condition and replace any parts that have deteriorated.

The filter pipe assembly, surrounding area, and solder remaining inside are extremely heated.

Ensure the unit is powered off and that it has cooled down enough before replacement work.

Remove the nozzle while pressing the nozzle lock release button.

Replace if damaged or cracked, as this can cause a reduction in suction pressure.

Remove the filter pipe assembly with a slight pull.

Inside of the filter pipe assembly was occupied over 70% by solder collected.

When the filter is soaked with flux, it becomes discolored and hard.

Check the condition and replace any parts that have deteriorated.

When the filter is soaked with flux, it becomes discolored and hard.