Lineup

Preheater/Preheater

Available in:

Six carbon heaters preheat the whole board immediately after turning the power on. Full-board heating and quick temperature ramping get the job done quickly when reworking or mounting post-production components to multilayer substrates that require greater thermal capacity. As it does not contaminate the air, the FR-870B also offers powerful support for a clean workplace environment in industrial applications.

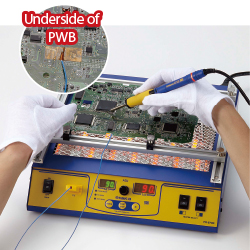

Non-contact heating allows preheating of double-sided boards, which hot plates cannot handle.

Auto mode step-heating method (maximum of three steps/step 1 to 3) heats PWBs slowly and evenly, letting you transmit 100% of the heat energy from a rework system and soldering iron. You'll never be forced to work with a higher set temperature due to insufficient heat again.

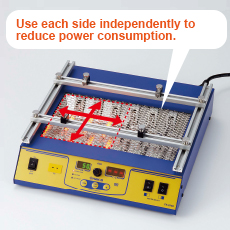

Power ModePower mode lets you control heater output using settings from 0% to 100%. |

T/C ModeOnce the temperature of the sensor attached to the board reaches the set temperature, the heater is on-off controlled so that the board temperature can be maintained at the set temperature. |

|

|

|

|

Auto mode provides three steps (Step 1 to 3) to create an optimal heating profile for the work in question, letting all operators consistently produce work of the same quality. Programs can be set for ten channels in each mode.

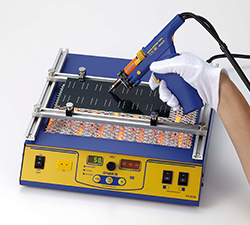

Once a PWB is positioned, boards of the same dimensions can be removed or attached in a single motion.

This design greatly supports continuous work.

Adjust screws to match board width and length.

Boards are hot after operation and must be handled with care.