MAINTENANCE/TROUBLESHOOTING/APPLICATION EXAMPLES

Top of Support & Service > MAINTENANCE/TROUBLESHOOTING/APPLICATION EXAMPLES > A new soldering tip does not fit the heating element!

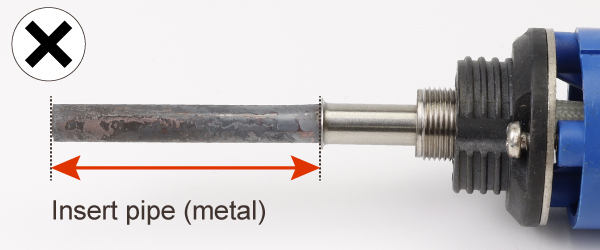

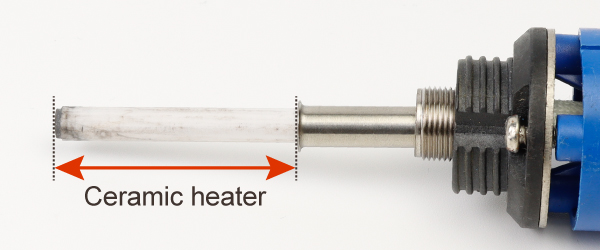

The flux entered inside the tip can cause seizing between the heating element and the insert pipe.

If such seizing occurs, the diameter of the heating element, to which the insert pipe seized, becomes too big for a new tip to fit.

Use a proper tool to remove the insert pipe.

The insert pipe that came off the tip is not reusable.

Replace the soldering tip and the heating element as well.

Every part is quite hot just after unplugging the iron. Please make sure that the metal parts are cool enough before starting the maintenance.

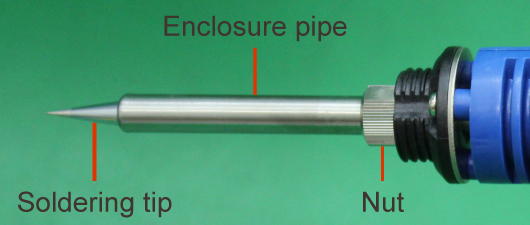

Loosen the nut.

Attach and detach the enclosure pipe.

Attach and detach the soldering tip.