MAINTENANCE/TROUBLESHOOTING/APPLICATION EXAMPLES

Top of Support & Service > MAINTENANCE/TROUBLESHOOTING/APPLICATION EXAMPLES > Knack for effective removal of solder using the desoldering wire

Wrong use of the desoldering wire may tear patterns from a P.W.B. or damage discrete components.

In order to remove solder well, make sure to take the preventive measure below: preliminary soldering improves heat conductance.

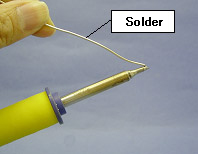

1. Apply a bit of solder to the tip of solder iron.

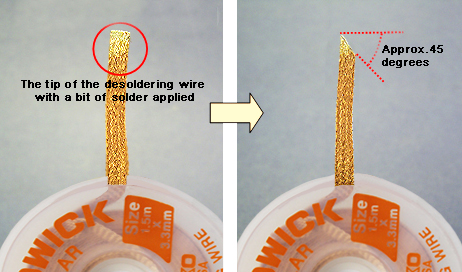

2. Apply a bit of solder to the tip of the desoldering wire. Cut the soldered tip of the wire at an angle of 45 degrees. Solder should remain attached.

|

|

|

Apply a bit of solder to the tip of the desoldering wire. |

Cut the soldered tip of the wire at an approx. 45 degrees. Solder should remain attached. In a similar manner, cut the wire with solder remain attached during desoldering if necessary. |