MAINTENANCE/TROUBLESHOOTING/APPLICATION EXAMPLES

Top of Support & Service > MAINTENANCE/TROUBLESHOOTING/APPLICATION EXAMPLES > How to use Shape Concave and examples

This type has a concave (or V-groove) at the end.

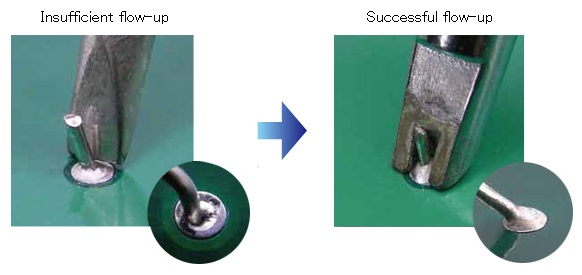

Features a wider tip surface that contacts the land pattern, which provides excellent heat supply to solder joints and ensures sufficient solder flow-up.

It is recommended for soldering involving multi-layered boards and increased PWB patterns due to higher current

[ Have the following problems? Try the concave type of tip ! ]

There are 2 types, concave and V-groove. And you can select and use the one according to your preference for specific flute width, angle of contact, heat capacity determined by flute shape, as well as land size and lead diameter.