What if solder does not wet on the tip?

If solder does not wet on the tip, it may be because of the oxidation of the tip.

It may be because of the tip oxidation if the solder does not wet on it or you do not see the good soldering.

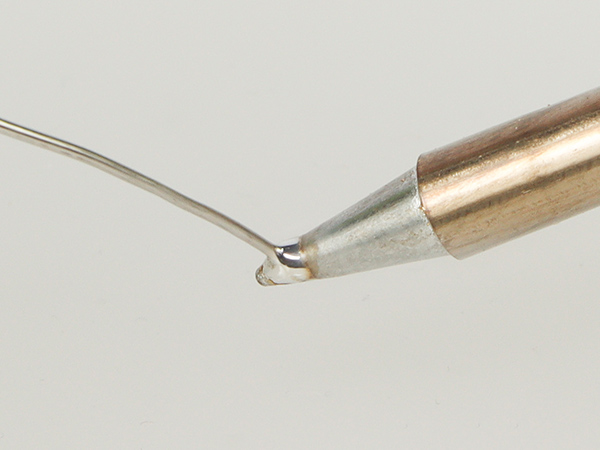

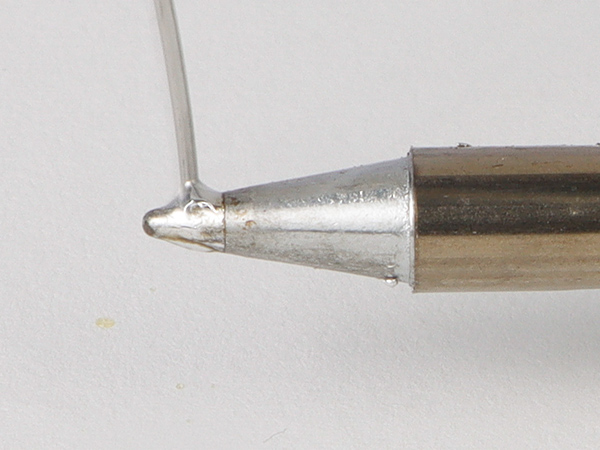

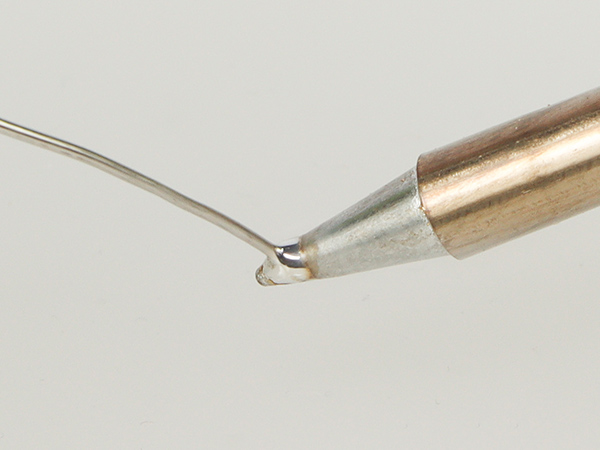

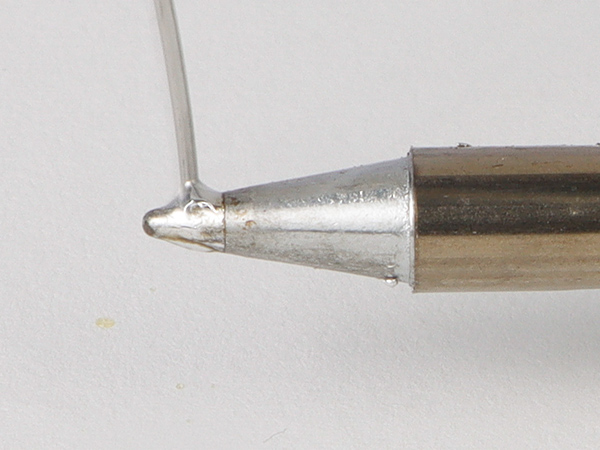

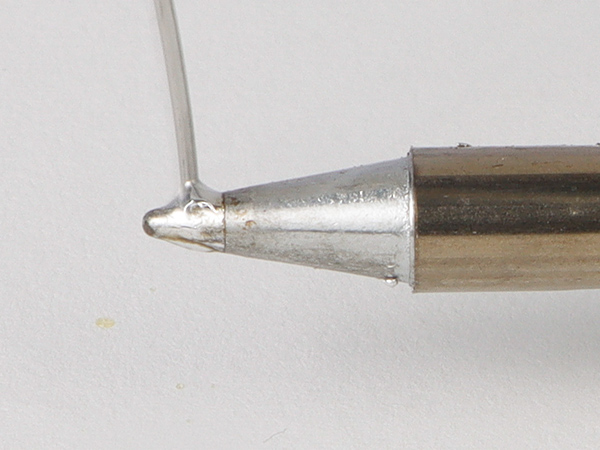

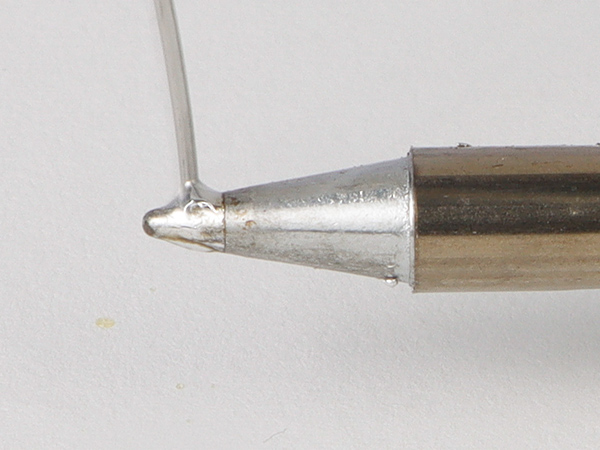

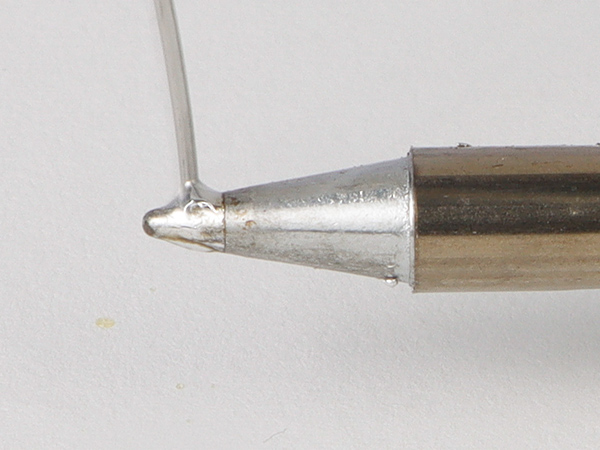

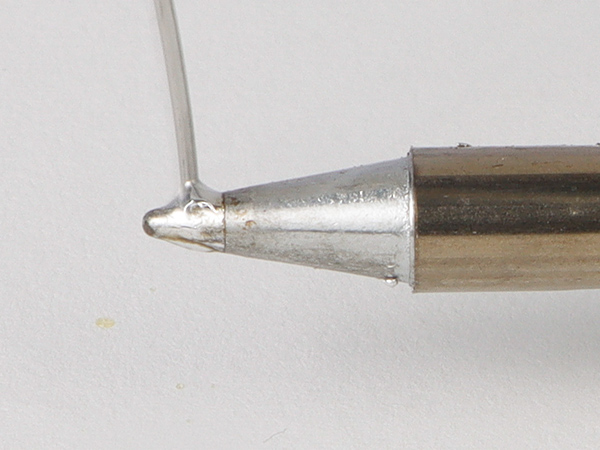

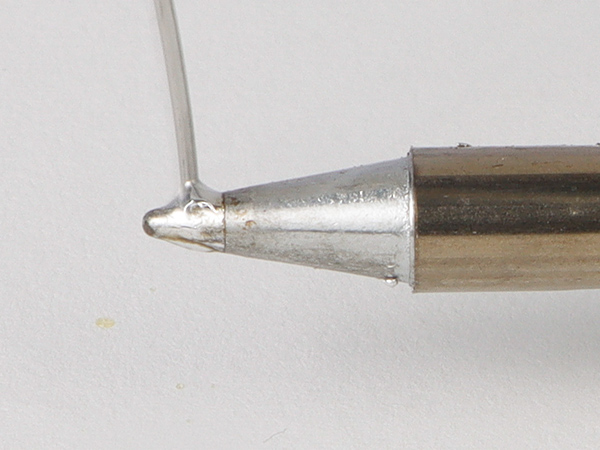

*Example of an oxidized tip blackened by the oxidation.

*Example of an oxidized tip blackened by the oxidation.

Solder does not wet on the tip and becomes spherical due to the surface tension.

How to handle an oxidized tip

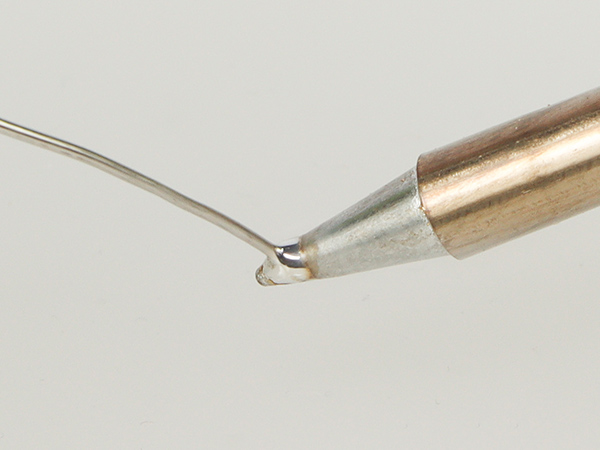

Solder would wet on the tip surface again after tip cleaning.

Tip cleaning with a cleaning wire and flux-cored solder

- Remove the oxides with a cleaning wire.

- Set the tip temperature at 250℃, and repeat the process of feeding solder to the tip and wiping it off several times.

- Once solder wets on the tip well, feed solder to cover the tip to prevent the tip oxidation at the end.

The product used

Cleaning wire 599B

Tip cleaning with the chemical paste, FS-100

Set the tip temperature at around 350℃.

- Dip the tip in the chemical paste, FS-100.

- Remove the chemical paste, FS-100, with a cleaning sponge or a cleaning wire.

- Feed solder to the tip and make sure solder wets on the tip well.

- Repeat the process of1to3until solder wets on the tip.

- Once solder wets on the tip well, feed solder to cover the tip to prevent the tip oxidation at the end.

The product used

Chemial paste FS-100

Tip cleaning with the tip polisher, FT-700

Set the tip temperature at around 350℃.

- Remove carbides and oxides with the tip polisher, FT-700.

- Dip the tip in the chemical paste, FS-100.

- Repeat the process of1to2 until removing oxides completely.

- Remove the chemical paste, FS-100, left on the tip.

- Once solder wets on the tip well, feed solder to cover the tip to prevent the tip oxidation at the end.

The product used

Tip polisher FT-700

If solder does not wet on the tip surface again even after the cleaning methods above, replace the tip with the new one.

How to prevent the tip oxidation

Point 1. Always keep the tip end coated with solder not to expose it to the air.

A soldering tip oxidizes upon contact with the air.

After the work, clean the tip with a cleaning sponge or a cleaning wire and feed solder to the tip end.

Point 2. Clean the tip with a cleaning wire.

Flux contained in HAKKO 599B cleaning wire will remain on the tip slightly and prevent the tip oxidation.

Cleaning Wire 599B

Point 3. Power off when not in use.

Point 4. Lower the set temperature. ( refrain from setting the temperature too high.)