Top of Products > Solder-Aid > ESD-SAFE products

ESD (electrostatic discharge) is defined as the transfer of electric charge, which takes place when two objects which have been charged to different electric potentials are brought in contact with one another or when two objects which have different electric potentials due to static induction are brought in contact with one another. ESD can cause product defects as well as equipment failures which result in an unforeseen accident. The most common example of damage caused by electrostatic discharge is when a charged worker or tool touches a grounded device which has a low resistance to static electricity.

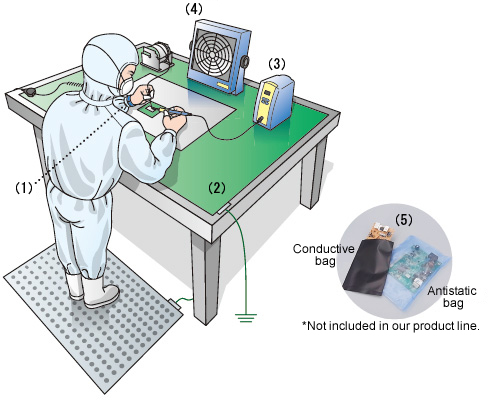

ESD Control Procedures basically involves the following 5 steps.

Wear an antistatic wrist strap.

Lay the ESD protective mat on the work bench to ground it.

Use the ESD protective tools.

Use the static eliminator (ionizer).

Store in antistatic bags.