Lineup

Preheater/Preheater

Available in:

The improved air outlet shortens preheat time compared with our conventional products.

Please refer to above values, which vary depending on soldering condition.

Pushing the "START/STOP" button at the end of work automatically activates the cool-down function.

An extension pipe with a lid is available for local heating.

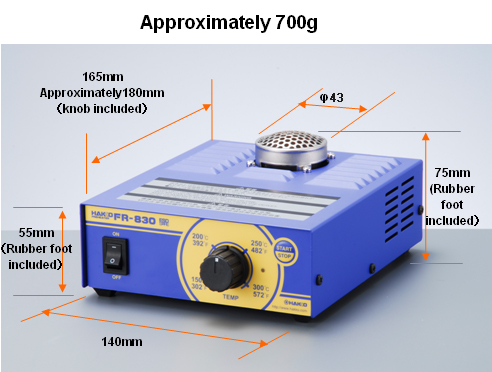

FR-830

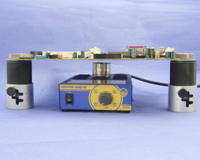

+Omnivise C1390C (2 used) (Rework system)

+Extension pipe/with backflow prevention lid B3263 (option)

FR-830 + Omnivise C1390C (2 used) (Rework system) + Extension pipe/with backflow prevention lid B3263 (option) Extension pipe: Used for local heating

Backflow prevention lid: When using in combination with SMD rework hot air, use the lid so hot air does not flow back into the FR-830 hot air outlet.

Always use the backflow prevention lid when the FR-830 switch is off.

FR-830

+ SMD rework station FR-803B (discontinued)

+ Rework fixture C1392B*

+ Omnivise C1390C* (2 used)

(*Rework system)

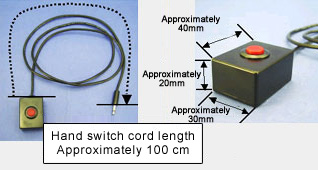

”Hand switch” and ”Foot switch” can be connected.

| Hand switch | Connection cord length: Approximately 100 cm Switch size: Approx. 30mm (W) × 40mm (D) × 20mm (H) When using the hand switch, switching is not possible on the main device.  |

|---|---|

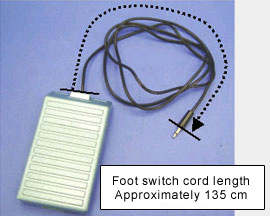

| Foot switch | Connection cord length: Approximately 135 cm

When using the foot switch, switching is not possible on the main device.  |

Measure temperatures of Hot Air Rework System and workpiece using the Temperature Probe for Hot Air Rework System (C1541) and thermometer (FG-100B/FG-101B) to protect the workpiece.

How to Use the Temperature Probe for Hot Air Rework System(C1541)

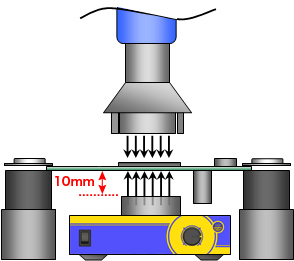

Please keep a gap between the hot air outlet and the PWB for more than 10mm to allow the air to flow. When there is not enough space for the air to flow, the fuse may blow up.

When should the optional Temperature Probe for Hot Air Rework System (C1541) be used?

When should the optional Temperature Probe for Hot Air Rework System (C1541) be used?

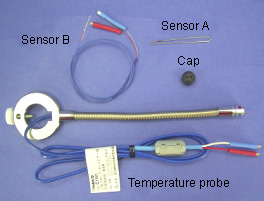

The Temperature Probe for Hot Air Rework System (C1541) is equipped with 2 types of sensors. Before measuring temperatures as follows, connect the sensor to the thermometer.

| Sensor A: | When measuring the temperature of hot air blown from the nozzle: Correcting thermal control can be made by confirming the temperature of the hot air that is actually blown. |

| Sensor B: | When measuring the temperature of applicable parts (workpieces): Rework can be performed without causing damage to the parts being reworked (QFP, etc.) |

How to Use the Temperature Probe for Hot Air Rework System(C1541)