Lineup

Soldering Iron/Solder Feed System

Available in:

As shown below, when solder is cut with a V-groove it enables the release of gas pressure generated by the flux, thereby suppressing splash.

However, because the V-groove exposes the flux to outside air the solder cannot be stored for a long period of time.

When using solder with the HAKKO 375, you can groove the solder that you require.

Test criteria

| Measurement method | Measure the amount of solder and flux splashing after solder is fed to the soldering iron. |

|---|---|

| Temperature setting for soldering iron | 350°C and 400°C |

| Solder | Lead-free (Sn-3Ag-0.5Cu) Halogen-free flux 0.3 mm dia., 1 mm dia. |

| Solder feed length | 50 mm |

Measurement graph of flux splash amount

0.3 mm dia. solder*Click here to enlarge

1 mm dia. solder*Click here to enlarge

0.3 mm, 0.5 mm, 0.6 mm, 0.8 mm, 1 mm dia.

Application Examples

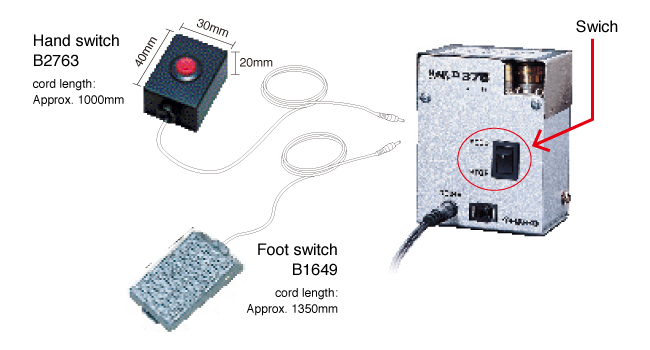

Control the amount of solder that is fed using the ON/OFF switch. Use an option switch or hand switch to increase functionality even more.